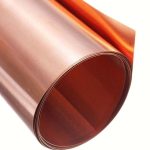

C10200 copper strip finds widespread use in various applications due to its unique combination of properties.

It is commonly employed in the production of electrical and electronic components, including conductors, connectors, and terminals.

Other applications include power generation and distribution systems, heat exchangers, and certain specialized manufacturing processes.

C10200 copper strip conforms to international standards to ensure consistency and quality.

ASTM B152 is a standard specification covering sheet, strip, and plate made from C10200 copper. This standard defines the chemical composition, mechanical properties, and other relevant characteristics.

ASTM B187 is another standard that covers C10200 in the form of bar, rod, and wire, providing specifications for these specific product types.

| Technique | Suitability |

|---|---|

| Soldering | Excellent |

| Brazing | Excellent |

| Oxyacetylene Welding | Fair |

| Gas Shielded Arc Welding | Good |

| Coated Metal Arc Welding | Not Recommended |

| Spot Weld | Not Recommended |

| Seam Weld | Not Recommended |

| Butt Weld | Good |

| Capacity for Being Cold Worked | Excellent |

| Capacity for Being Hot Formed | Excellent |

| Forgeability Rating | 65 |

| Machinability Rating | 20 |