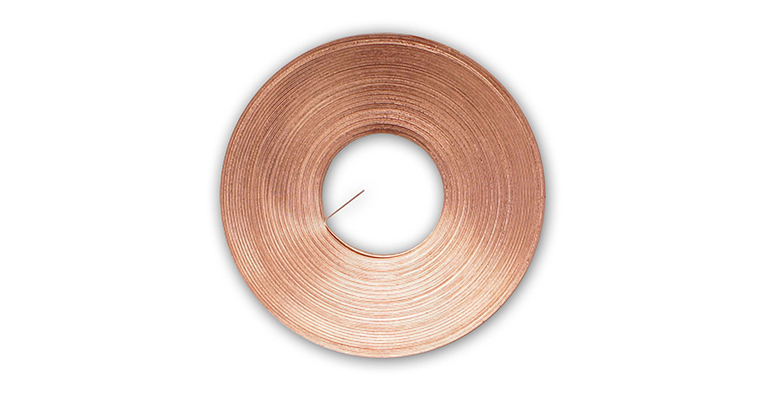

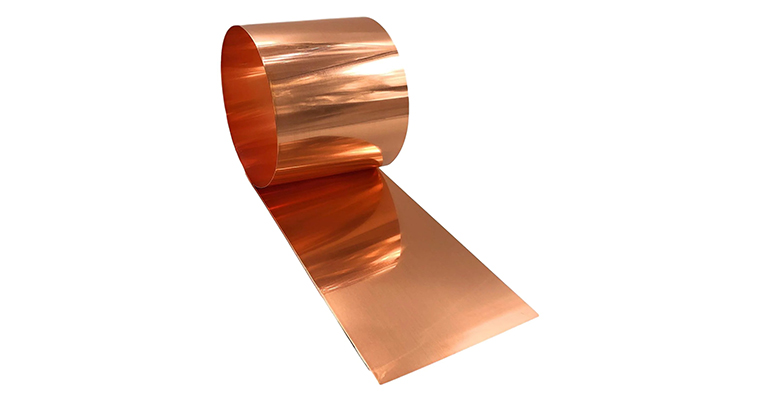

T2 copper strip, conforming to the Chinese standard GB/T 5231, represents a high-purity oxygen-free copper (OFC) characterized by a minimum copper content of 99.95%. Renowned for its exceptional electrical conductivity, T2 copper is particularly well-suited for applications where efficient transmission of electrical currents is paramount. Its oxygen-free nature ensures minimal impurities, reducing the risk of oxidation and contributing to the material’s corrosion resistance. This makes T2 copper strip a preferred choice in various industrial sectors, including electronics, power transmission, and telecommunications, where the reliability of electrical components is critical. The malleability and ductility of T2 copper further enhance its versatility, allowing it to be easily shaped and formed to meet the specific requirements of diverse manufacturing processes.

In practical applications, T2 copper strip finds utility in the production of electrical and electronic components, such as connectors, busbars, and conductors. The high purity of T2 copper ensures minimal signal loss and heat generation, making it an essential material for high-performance devices and systems. Its corrosion resistance is valuable in environments where exposure to moisture or aggressive substances is common. Additionally, T2 copper’s conductivity and other physical properties contribute to its use in automotive components and various manufacturing applications, reinforcing its position as a reliable and efficient material in the world of electrical engineering and industrial processes.

| Property | Value (Typical Range) |

|---|---|

| Tensile Strength | 215 – 250 MPa |

| Yield Strength | 75 – 200 MPa |

| Elongation at Break | 35% – 50% |

| Hardness (Vickers) | 50 – 80 HV |

| Modulus of Elasticity | 110 – 130 GPa |