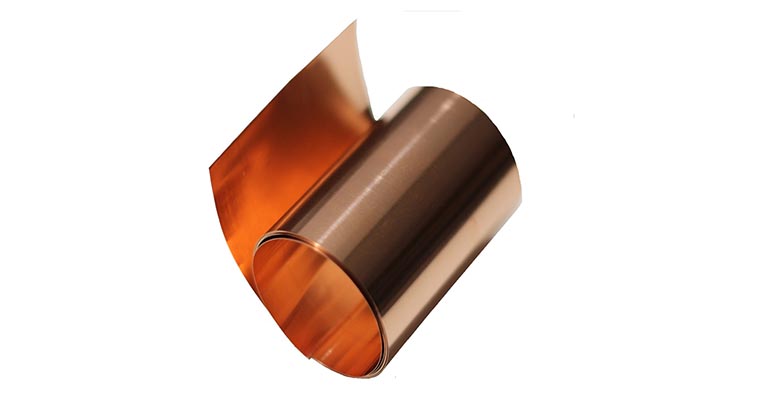

C12000 copper strip, a versatile and high-performance copper alloy, stands as a remarkable material in the world of engineering and manufacturing. Renowned for its exceptional electrical conductivity, this alloy is a popular choice in industries where efficient electrical conduction is paramount. Its outstanding conductivity ensures that it is widely used in the production of electrical wires, connectors, and various components in the electrical and electronics sectors.

Beyond its electrical properties, C12000 copper strip is prized for its malleability and formability. Its ability to be easily shaped and formed into intricate designs or specific dimensions makes it a valuable material in various manufacturing processes. Whether used in architectural applications, heat exchangers, or as a base material for artistic creations, C12000 copper strip’s versatility and exceptional properties make it a cornerstone in modern industry and design.

| Melting Point – Liquidus°F | 1981 |

|---|---|

| Melting Point – Solidus°F | 1981 |

| Densitylb/cu in. at 68°F | 0.323 |

| Specific Gravity | 8.94 |

| Electrical Conductivity% IACS at 68°F | 98 (1) |

| Thermal ConductivityBtu/ sq ft/ ft hr/ °F at 68°F | 223 |

| Coefficient of Thermal Expansion 68-21210 to -6 power per °F (68 – 212°F) | 9.4 |

| Coefficient of Thermal Expansion 68-39210 to -6 power per °F (68 – 392°F) | 9.6 |

| Coefficient of Thermal Expansion 68-57210 to -6 power per °F (68 – 572°F) | 9.8 |

| Specific Heat CapacityBtu/ lb /°F at 68°F | 0.092 |

| Modulus of Elasticity in Tensionksi | 17000 |

| Modulus of Rigidityksi | 6400 |