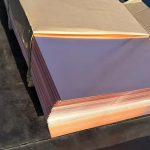

C11600 copper sheet is a high-performance copper alloy, by adding trace amounts of silver elements to copper, significantly improving its softening temperature (recrystallisation temperature) and creep strength. At the same time, it still maintains the original high electrical and thermal conductivity of copper, as well as good plasticity. This makes C11600 copper sheet ideal for use in a wide range of fields such as electrical, electronics, and communications, for the manufacture of a variety of components that require excellent electrical conductivity and strength.

C11600 copper sheet not only possesses excellent physical and mechanical properties, such as wear resistance, electrical contact and corrosion resistance, but it also has excellent machinability. This makes C11600 copper sheet easy to machine into a variety of shapes and sizes during the manufacturing process for a wide range of complex applications. Whether it is in the rectifier sheet of electric motors, conductors for generator rotors, or in construction, medical and other fields, C11600 copper sheet has demonstrated its excellent performance and wide application prospects.

| Material | C11600 Copper Alloy |

| Chemical Composition | Cu: 99.90%, Ag: ≥0.085% |

| Conductivity | Excellent (High purity copper ensures high conductivity) |

| Corrosion Resistance | Good (Excellent resistance to oxidation and sulfidation) |

| Mechanical Strength | High (Due to the addition of silver and other elements) |

| Workability | Excellent (Can be processed by various methods such as casting, forging, rolling, drawing) |

| Ductility | Good (Allows for shaping into various forms and sizes) |

| Tensile Strength | High (Can be further improved through cold working) |

| Creep Strength | Elevated (Improved by the addition of silver) |