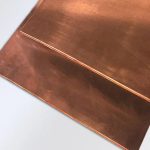

C37100 copper plate, as a high-performance lead brass material, stands out for its excellent cutting and machining performance and corrosion resistance. Its tensile strength is up to more than 390MPa, the yield strength is also more than 110MPa, while the elongation can reach more than 30%, these excellent mechanical properties make C37100 copper plate in machinery manufacturing, These excellent mechanical properties make C37100 copper sheet popular in the fields of machinery manufacturing, automobile, motorbike, electrical appliances and electronics. Whether it is to manufacture precision parts or structural components, C37100 copper plate can easily cope with, showing a strong potential for application.

Not only are the mechanical properties of C37100 copper sheet outstanding, but its machinability and surface quality are equally impressive. This copper plate is easy to cut and less prone to cracks or deformation during processing, greatly improving productivity. At the same time, it also has good welding performance and polishing performance, making the surface treatment easier, the finished product surface is smooth as a mirror, superior quality. In addition, C37100 copper plate also shows good stability to general corrosive environments, ensuring long-lasting durability in a wide range of usage scenarios. Therefore, C37100 copper plate plays an irreplaceable role in both high-end machinery manufacturing and hardware accessories in daily life.

| Melting Point – Liquidus°F | 1660 |

|---|---|

| Melting Point – Solidus°F | 1630 |

| Densitylb/cu in. at 68°F | 0.307 |

| Specific Gravity | 8.5 |

| Electrical Conductivity% IACS at 68°F | 26 |

| Thermal ConductivityBtu/ sq ft/ ft hr/ °F at 68°F | 67 |

| Coefficient of Thermal Expansion 68-57210 to -6 power per °F (68 – 572°F) | 11.4 |

| Specific Heat CapacityBtu/ lb /°F at 68°F | 0.09 |

| Modulus of Elasticity in Tensionksi | 14000 |

| Modulus of Rigidityksi | 5300 |