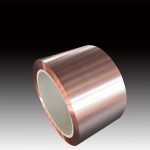

C41100 copper strip is a high-performance copper alloy material known for its high electrical conductivity and good mechanical properties. It has a wide range of applications in the electrical and electronics industry, especially in the fields of circuit boards, connectors and wires, providing stable current transmission and reliable mechanical support. In addition, C41100 copper strip has excellent corrosion resistance and can maintain its performance for a long time in humid and corrosive environments, ensuring the long-term stable operation of equipment.

The high electrical conductivity of this copper strip not only ensures efficient power transmission, but also reduces energy losses and improves the energy efficiency of the equipment. At the same time, its good mechanical properties make it not easy to deform during processing, can adapt to a variety of complex molding process, to meet the needs of different application scenarios. Whether it is precision electronic components or large electrical equipment, C41100 copper tape can provide excellent performance and reliability.

| Melting Point – Liquidus°F | 1905 |

|---|---|

| Melting Point – Solidus°F | 1870 |

| Densitylb/cu in. at 68°F | 0.318 |

| Specific Gravity | 8.8 |

| Electrical Conductivity% IACS at 68°F | 32 |

| Thermal ConductivityBtu/ sq ft/ ft hr/ °F at 68°F | 75 |

| Coefficient of Thermal Expansion 68-21210 to -6 power per °F (68 – 212°F) | 10.2 |

| Specific Heat CapacityBtu/ lb /°F at 68°F | 0.09 |

| Modulus of Elasticity in Tensionksi | 18000 (1) |

| Modulus of Rigidityksi | 6700 |